Metal is considered to be a very important materials in many fields - from building and construction of houses, making of cars, and even used in airplanes. And there are plenty of ways that people can form metal for all kinds of products that can be used. The die casting shaping method is a standard metal shaping method. So here in this piece we will discuss what die casting parts is, how it works, and when and why it may be better than some other methods of shaping metal.

What is Die Casting?

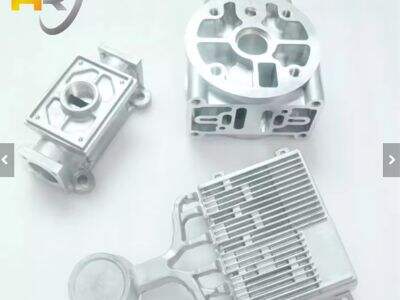

Huarui Die casting If you have a special need for an aluminum component, die casting can provide it. We use a mold which is a type of container that is shaped just like the part we want to create. Once it is poured in, the melted metal cools off and solidifies itself in this mold, resulting in a solid metal part. When it hardens, the piece can be removed from the mold. Making metal parts this way is very useful and has many advantages over other means of production.

Advantages of Die Casting:

1) High Precision: a good thing about the die casting is the parts make with high precision. Molds are meticulously designed to produce high quality, low secondary process parts. It is critical for things like automotive parts, electronic housings, and medical devices that need to snap nicely together.

Less Waste: One of the best qualities of Die casting part is that it generated a very low waste. Leftover pieces of scrap metal can also be recycled and reused easily. Die casting also emits less waste, which is a better option for our planet. Also, the process is mostly machine-run, which is good for keeping the costs low and production fast.

Why is Die Casting Better?

There are some very good reasons as to why die-casting tends to be a better option than other metal shaping methods.

Considerable Parts: The parts that are manufactured using the die casting are usually more solid and durable than other processes. The reason is that the melted metal is injected into the mold with high pressure. The pressure allows for the making of a thick and resistant material.

Speed:

Die casting is a quick method of making parts, which is beneficial for mass-producing many parts. This rapid production process makes die casting highly suitable for large orders with a large quantity of identical parts.

How Die Casting Stands Out:

For example, one of the things that makes die casting special is its capability of delivering complex parts with high accuracy. Die casting can produce complex, detailed parts. Machining, stamping, and other processes can produce simpler parts, but these methods may require further steps to finish the surface and improve tolerances.

Comparing to Older Methods:

Die casting is a more modern method of shaping metals than older techniques such as sand casting and investment casting. Classic techniques can also provide good elements, but they generally call for additional finishing and polishing. This additional labor also can contribute to the cost to manufacture the parts and prolonged schedules.” Die casting, on the other hand, is a quick and efficient process that creates parts accurate enough to reduce finish cost and time.

Pros and Cons:

Like any process, die casting has its pros and cons:

Pros: Die casting typically produces an accurate part with little, if any, waste and is not an expensive process. Die Castings or the strong and durable parts are often preferred in many industries because of the numerous applications.

Cons: The disadvantages of die casting are: (For instance, the upfront cost to create the molds has some prohibitive costs, making them less ideal for small production runs.) Furthermore, not all kinds of metals can be die cast, and certain materials may require different processes for forming.

EN

EN