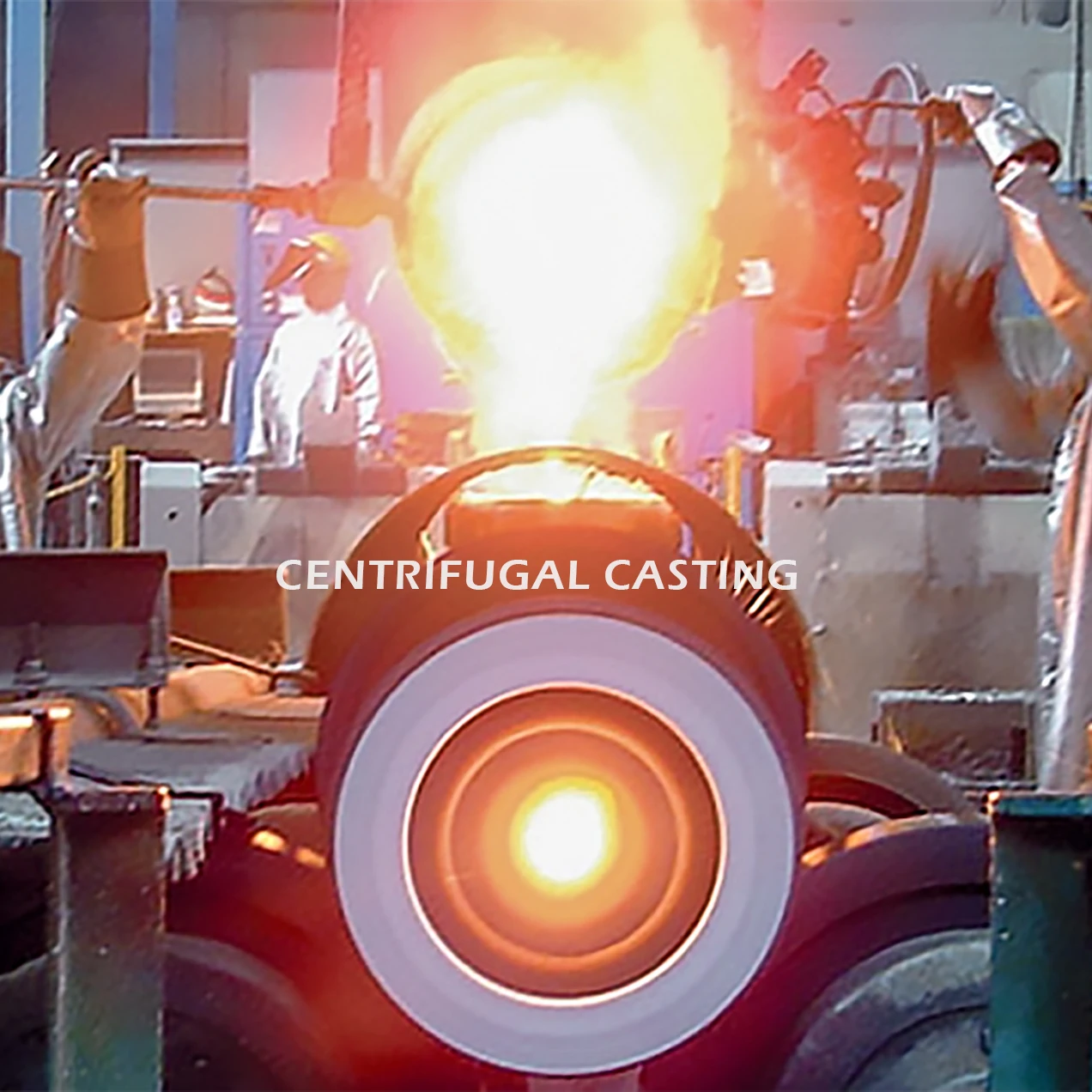

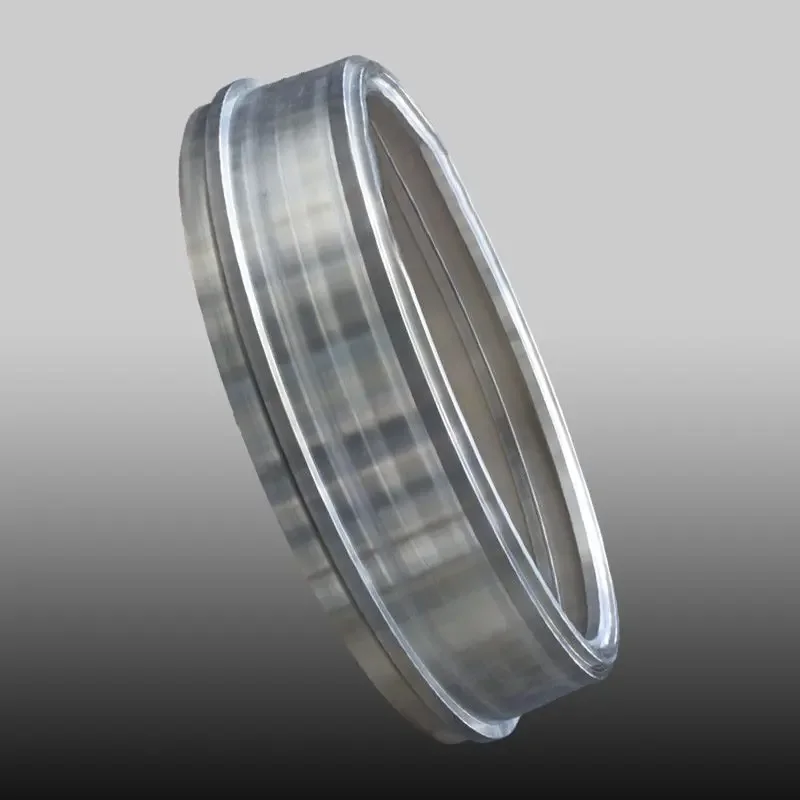

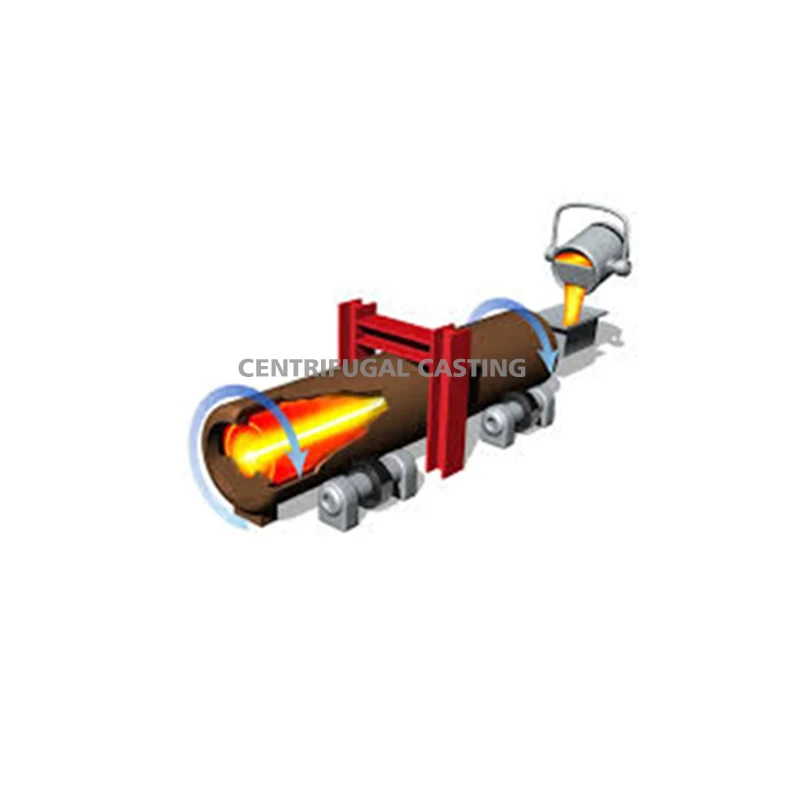

foundry manufacturers precision custom vacuum cast iron part zinc metal aluminum die casting parts services centrifugal casting

Product Description

element Materials

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

five |

S,P |

intro |

ZG310-570

|

0.50 |

0.6 |

0.90 |

≤ 0.040

|

Low plasticity and toughness, low temperature resistance, low cost |

||||

35CrMo

|

0.32 -

0.37

|

0.17- 0.37

|

0.40-0.70 |

0.80-1.10 |

0.15- 0.25

|

≤ 0.035

|

High strength, toughness and hardness, high temperature resistance, low cost |

||

0.30- 0.38

|

0.17-0.37 |

0.40-0.70 |

1.00-1.30 |

0.20- 0.30

|

0.10-0.20 |

≤ 0.035

|

Performance better than 35crmo, low cost |

||

0.30-0.37 |

0.6-0.9 |

0.40-0.90 |

0.40-0.90 |

0.06-0.90 |

0.40-0.50 |

≤ 0.035

|

High strength and toughness, high temperature resistance, high cost |

||

KCP-12

|

0.20-0.30 |

≤0.60 |

0.90-1.10 |

0.40-0.90 |

1.00-1.50 |

0.30-0.50 |

≤ 0.040

|

High strength and toughness, high temperature resistance, high cost |

1. Annealing

Annealing is the heating of the steel spool to the proper temperature and then the slow cooling of the steel casing to or near equilibrium.

2. Normalization

Normalizing is to cool the steel spool after reaching the right temperature, the effect of normalizing is similar to annealing, and it is usually used to improve the cutting properties of the material, and sometimes it is also used for low requirements for certain parts as a final heat treatment.

3. Quenching

Quenching is a rapid cooling process after heating a workpiece in a quenching medium of water, oil or other organic salts and organic water. Steel hardens after quenching, but at the same time becomes brittle.

4. Tempering

Tempering is done to reduce the brittleness of the steel. The quenched steel is kept at 650 °C above room temperature for a long time and cooled again, a process known as tempering.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Our Services

EN

EN