china gieterij fabrikante presisie aanpasbare oem gieterts deel sink metaluminium dye casting dele diens dye aluminium

Produkbeskrywing

Produkparameters

Proses Inleiding

Die vormgesl is 'n metaalvormproses wat geken word deur hoë druk toe te pas op die smeltemetaal deur gebruik te maak van die holte van die vorm. Vorme word gewoonlik gemaak van hoërsterkte leagies, en hierdie proses is tot 'n sekere mate soortgelyk aan inspuitingsslagting.

Vervaardigersnaam |

Sterftestommingsdiens |

Vormmateriaal |

Aluminium, SKD61, 45#, P20, H13, 718, 1.2344, 1.2738 en so voort |

Materiaal |

Aluminium: ADC12, ADC10, A360, A356, A380, A413, B390, EN47100, EN44100 of geskik. Sink: ZA3#, ZA5#, ZA8# of geskik op bestelling. Magnesium: AZ91D, AM60B of geskik op bestelling. |

Oppervlaktebehandeling |

Werkswinkelafwerkings, Poederkoting, Poetsing, Borstelwerk, ens. |

Tekenformaat |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, ens. |

Diep verwerking |

CNC / Sny / Stempel / Toesig / Tapping / Boring / Fries |

Toepassing |

meubels, Bedryfsaanpassings en Bou- en Versiering, ens. |

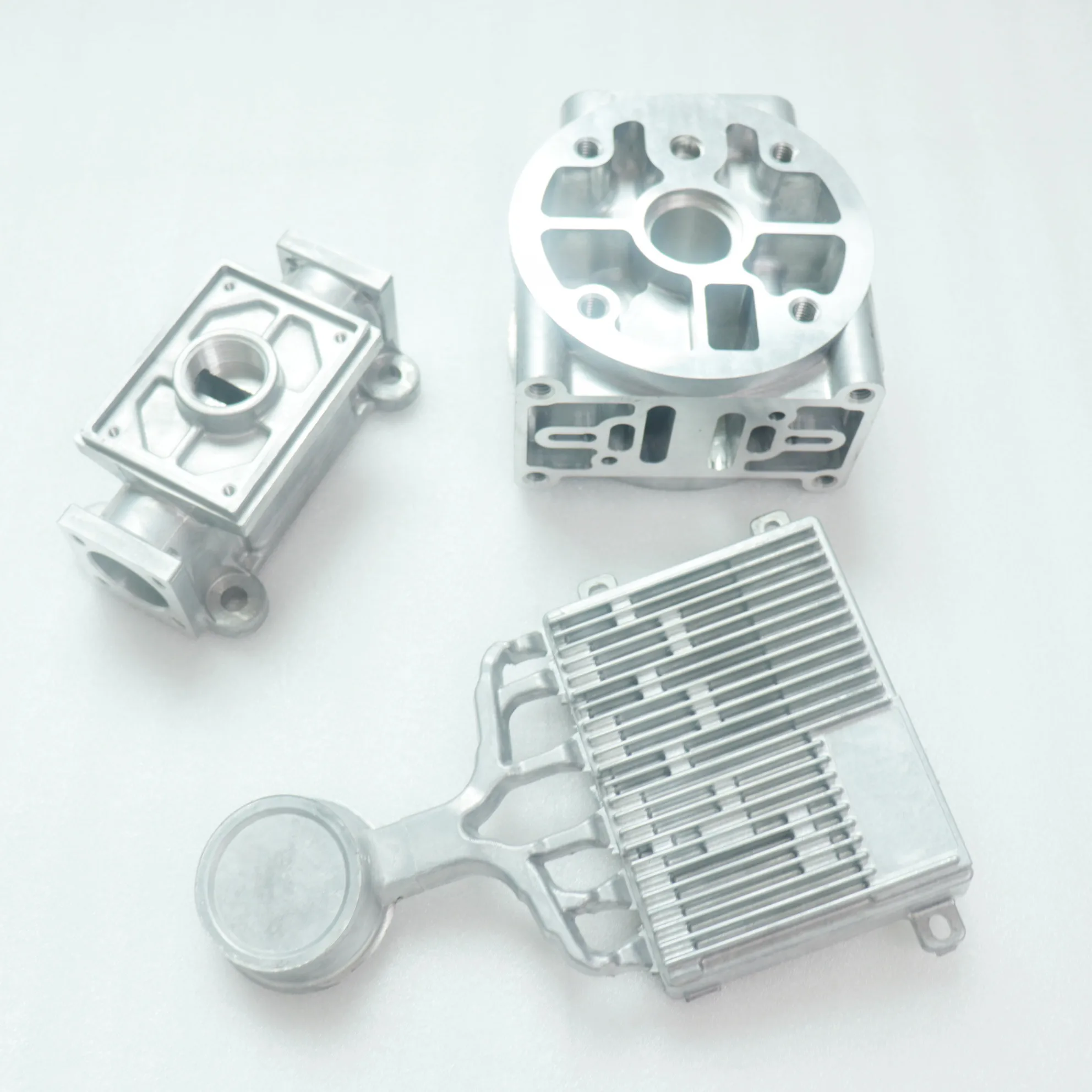

Besonderhede Beelde

Bedryfsprofiel

Waarom Kies Ons

Jy is baie welkom om ons te besoek onder vele leweranciers

1.) Ons spesialiseer ons in die verskaffing van geskikte verwerking dienste vir drukgieting, blaaier, CNC en draaibank. 2.) 24 urelyn diens & Vinnig offerte. 3.) Ons het baie ryk ervaring, jy is welkom om met ons te praat wanneer ook nie oor jou vereistes of produkte wat jy wil aanpas. 5.) 100% Kwaliteitstoets voor aflewering, en kan kwaliteitstoetsformulier verskaf. 6.) Ons produkte en dienste is wydlopend deur klante lokaal en internasionaal gepreis. 7.) ISO sertifikaat Fabriek. 8.)Om jou te help vinniger en makliker goed te ontvang, ondersteun ons see, land, ekspres en lugvervoer.

Ons het 'n baie streng kwaliteitbeheerproses

Inkomende kwaliteitsbeheer (IQC) – Alle inkomende ruwe materiaal word geïnspekteer voordat dit gebruik word. Kwaliteitsbeheer tydens proses (IPQC) – Voer inspeksies uit gedurende die vervaardigingsproses. Eindkwaliteitsbeheer (FQC) – Alle afgeronde produkte word geïnspekteer volgens ons kwaliteitsstandaard vir elke produk. Uitgaande kwaliteitsbeheer (OQC) – Ons QC-span sal 100% volle inspeksie uitvoer voordat dit uitgestuur word vir versending. Juiste kwantumprosedure – Vir produkte wat nie deur die kwaliteitsbeheer gaan nie, sal hulle spesiaal gemerk word en weggewerp word.

Klant Terugvoer

Sertifikate

VRG

Vraag 1: Wat is die spesifieke vervaardigingsproses? |

Dielontwerp→Dieevorming→Smelting&legging→Kwaliteitsbeheer→Dielgieting→verwyder burres→Kwaliteitsbeheer→Oppervlakbehandeling→Kwaliteitsbeheer→Verpakking→Kwaliteitsbeheer→Verskeping→Navorse diens na verkoop. |

Vraag 2: Hoe gou kan ek monsters kry? |

Afhanklik van jou spesifieke projek neem dit gewoonlik 10 tot 20 dae. |

Vraag 4: Kan jy bewerkingsdele maak gebaseer op ons monsters? |

Ja, ons kan meting doen gebaseer op jou monsters om tekeninge te maak vir die vervaardiging van bewerkingsdele. |

V5: Is dit moontlik om te weet hoe my produkte vorder sonder om jou maatskappy te besoek? |

A5: Ons sal 'n gedetailleerde produksieskedule aanbied en weeklikse verslae stuur met digitale prentjies en videos wat die masjineroprogress wys. |

EN

EN