Pródachta

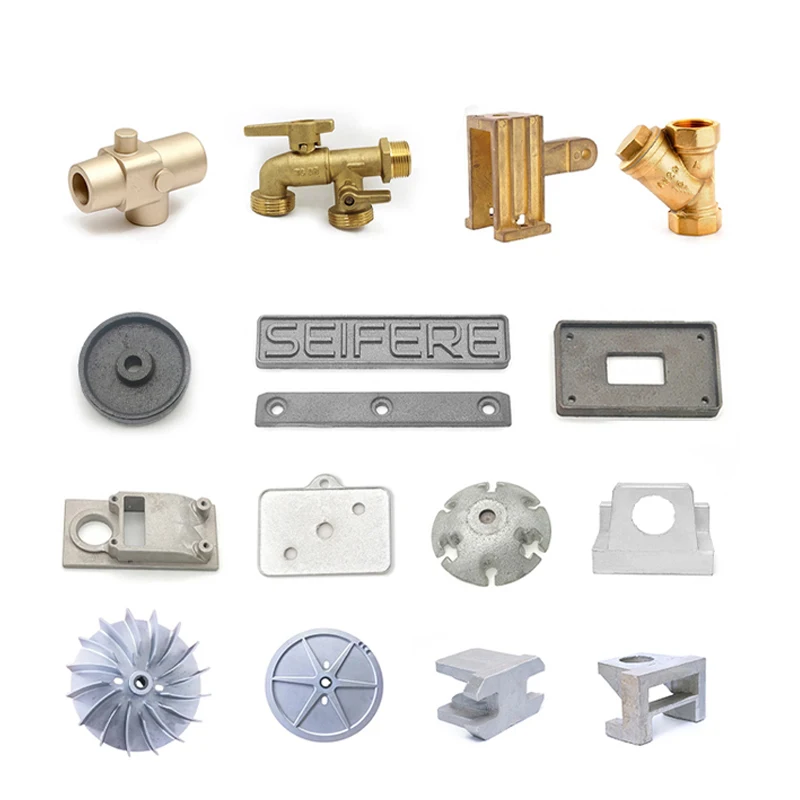

féineolas féiniúla téarmaíocht síneadh fhearrmhaireachta centrifugal cast iron rann zinseal metáil alúimínium casting comhlachta ranna vacuum centrifugal casting

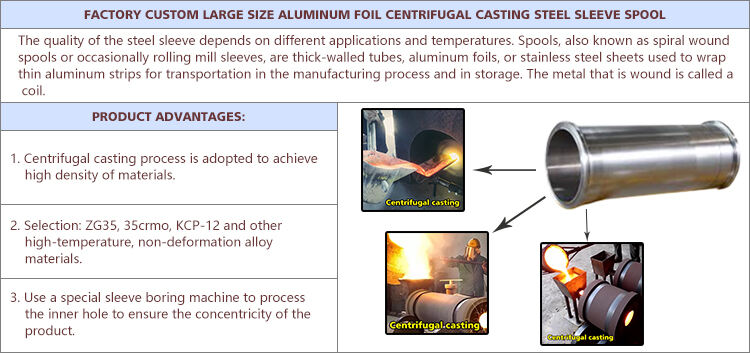

Cur síos ar an gcrann

Huarui

Is fíor go bhfuil Huarui mar chomhthionól éadrom a díríonn ar phrágais fúar chóiriúla a dhéanamh faoi sheasamh, páirteanna féin-ghlaoch castaíochta airgead, cás zinc agus aluminum, agus glaoch castaíochta seo is féin-ghlaoch. Tá ár n-athruithe déanta de réir infheistí taobh istigh, ag baint úsáide as na hábhar is déanaí agus próiseas chun cinntiú tuiscint iontach ar an gceangal

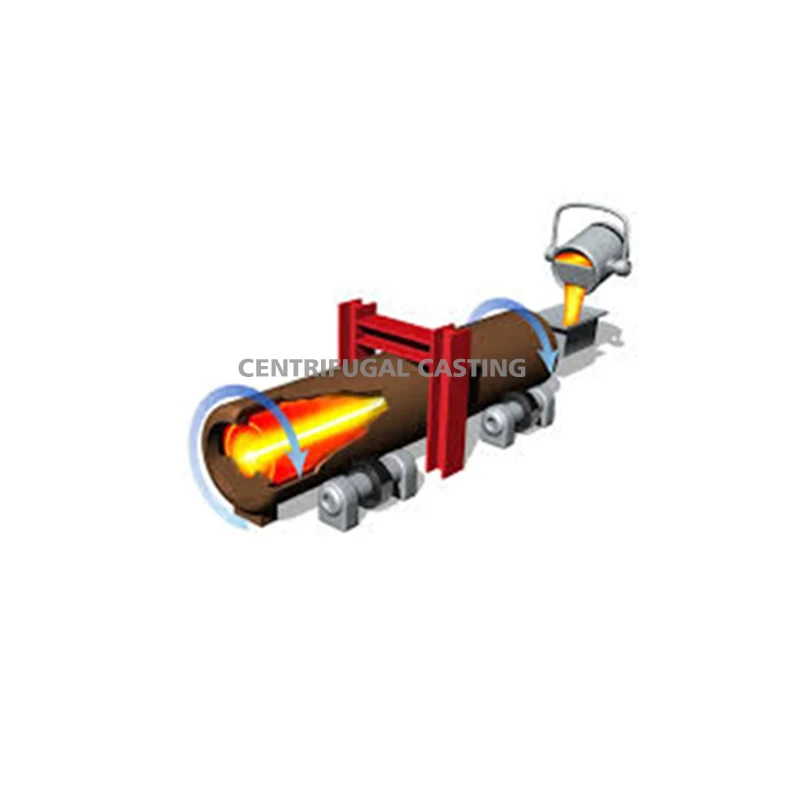

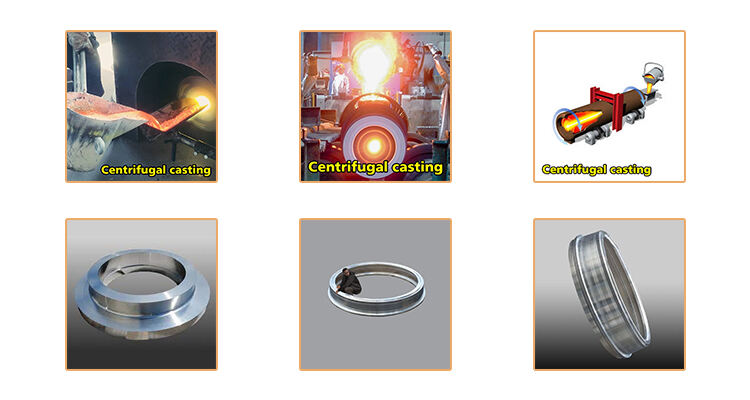

Is é an próiseas castaíochta féin-ghlaoch éard atá ag teacht leis an gcás téarmann ina n-úsáidtear i mbealach mold ag snámh, cinntiú go bhfuil gruaig ag feabhsú comhthéarnach, comhréire láidir. Is féin-ghlaoch seo atá déanta don chuid is fiú den pháirt ón gcustaiméir i gcomhairle Huarui, agus cinntíonn ár n-ionadai tsaothair éagsúla go ndéanfaidh gach casadh. Táimid ag úsáid eitlíocht ard rata agus módaí chun an rud is brónnaithe seo a chruthú ó scileanna éadrom go dtí scileanna córasacha is cómhlachtach

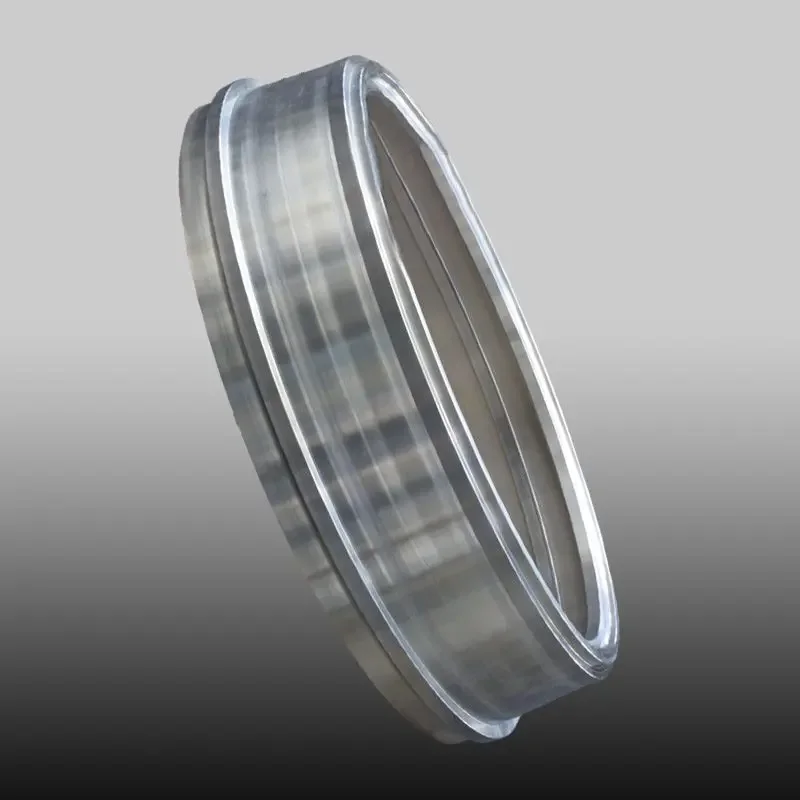

Tá ár gcomhphléaráin chrua chainteálta cast iarn mar phríomh-bhunachar go deo don fheabhsú agus an oiriúnacht don scileanna éagsúla, faoi láthair san aeróspae, meicniúlacht, ceara mór, agus go leor eile. Is léir nach bhfuil aon níos fearr ná an iarn chum casting díolta agus teann. Tá na héadóirí againn, a bhfuil acu spriocaireacht ar fud an domhain, ag obair ar chomhphléaráin iarn chainteálta do chéim ar bith nó do chineál ar bith, ag cinntiú go ndéanann siad an-taispeántas ar aghaidh na gcustaiméirí atá ag glacadh leo.

Ina choinne sin féin, is féidir leat comhphléaráin uaine, airgead agus alcamhna chainteálta a fháil freisin. Tá an uaine mar phróduct thart ar fad fliuch agus é seo mar thoradh ar an tuiscint a bhfuil againn ar an gcoirpéis agus an t-athrú coirpéis, ag cinntiú go bhfuil sé ceart go leor don úsáid. Tá ár n-ionsaí uaine chainteálta a dhéanamh ag úsáid na hathrúcháin is déanaí agus na n-inneall is fearr, ag cinntiú go bhfuil siad ag feabhsú ar fud an domhain.

Is é an alabainn íomhá aon phríomh-úsáid i luchtú fheabhsú, mar thoradh ar an gcuí don chéim go hiontach. Feabhsaithear na comhponaintí alabainne againn ag baint úsáide as téicniúcháin agus uirlisí láistigh, cinntiú go ndéanann siad an-mhéid le haithint agus feabhsuithe.

Ag Huarui, bímid ag tabhairt aitheanta ar chásáil fhuascailte vacuüm, a chuirfidh isteach faoi scáth níos soiléir chun comhpleacht is fearr den chéad a bheith acu gan gluaiseachtaí nó difeáltaí. Is maith an téacs é seo chun comhponaintí ábharacha fuascailte agus níos deacair a chruthú ag iarraidh ar an gcéad measúnú agus deifir.

Tá ár gcóras fíor phríobháideach faoi Huarui agus brón orm tosú leis an gcluiche. Chun beartas a chur ar pháirteanna castála ionaid iargúirt, eilimh is ainmneacha atá ag obair ar theicneolaíocht agus comhthéadúlacht nua-aimseartha, nó castáil ionaid iargúirt faoi bhunús, táimid ag obair go soiléiriúil agus go soiléir le linn dúinn. Bíme i dtaobh r-phost dúinn don fhaisnéis breise conas is féidir linn cabhrú leat agus do phroject inniu amach.

eileamén Ábhair

|

C |

Sea |

Mn |

Cr |

Ni |

Mo |

five |

S, P |

réamhrá |

ZG310-570

|

0.50 |

0.6 |

0.90 |

≤ 0.040

|

Iompar íoctha agus éadromacht íoctha, íoctha íoctha faoi théamhracht, íoctha íoctha faoi chósta |

||||

35CrMo

|

0.32 -

0.37

|

0.17- 0.37

|

0.40-0.70 |

0.80-1.10 |

0.15- 0.25

|

≤ 0.035

|

Neamhspleáchacht ard, neamhspleáchacht agus neamhspleáchacht ard, téamhracht ard, cósta íoctha |

||

35CrMov |

0.30- 0.38

|

0.17-0.37 |

0.40-0.70 |

1.00-1.30 |

0.20- 0.30

|

0.10-0.20 |

≤ 0.035

|

Níos fearr ná 35crmo, cothrom le costas íochtarach |

|

35NiCrMo |

0.30-0.37 |

0.6-0.9 |

0.40-0.90 |

0.40-0.90 |

0.06-0.90 |

0.40-0.50 |

≤ 0.035

|

Féinmheon agus tuillíocht airde, comhluadar teoraimh airde, costas airde |

|

KCP-12

|

0.20-0.30 |

≤0.60 |

0.90-1.10 |

0.40-0.90 |

1.00-1.50 |

0.30-0.50 |

≤ 0.040

|

Féinmheon agus tuillíocht airde, comhluadar teoraimh airde, costas airde |

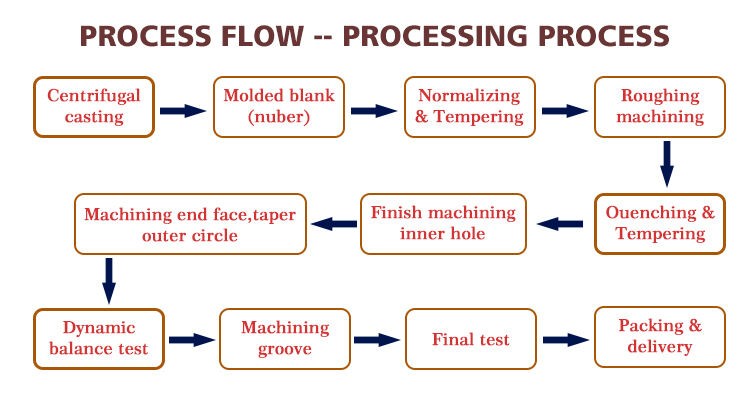

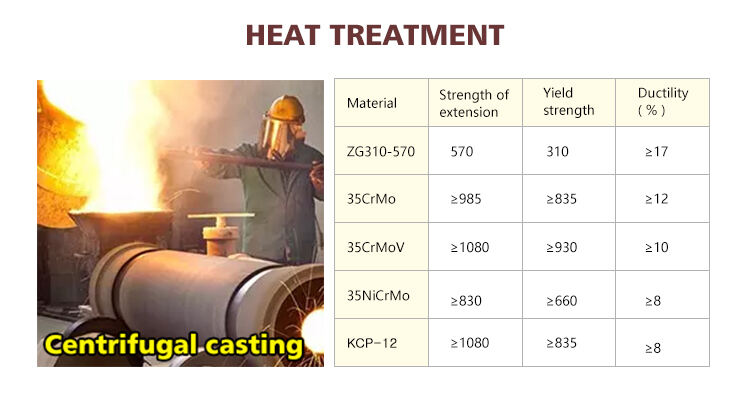

1. Ath-théamh

2. Nornálaíocht

3. Leathnú

4. Léim théamh

EN

EN