china foundry manufacturers precision custom oem cast iron part zinc metal aluminum die casting parts services die cast aluminum

Product Description

Product Paramenters

Process introduction

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding.

Craft name |

Die casting parts service |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Deep Processing |

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

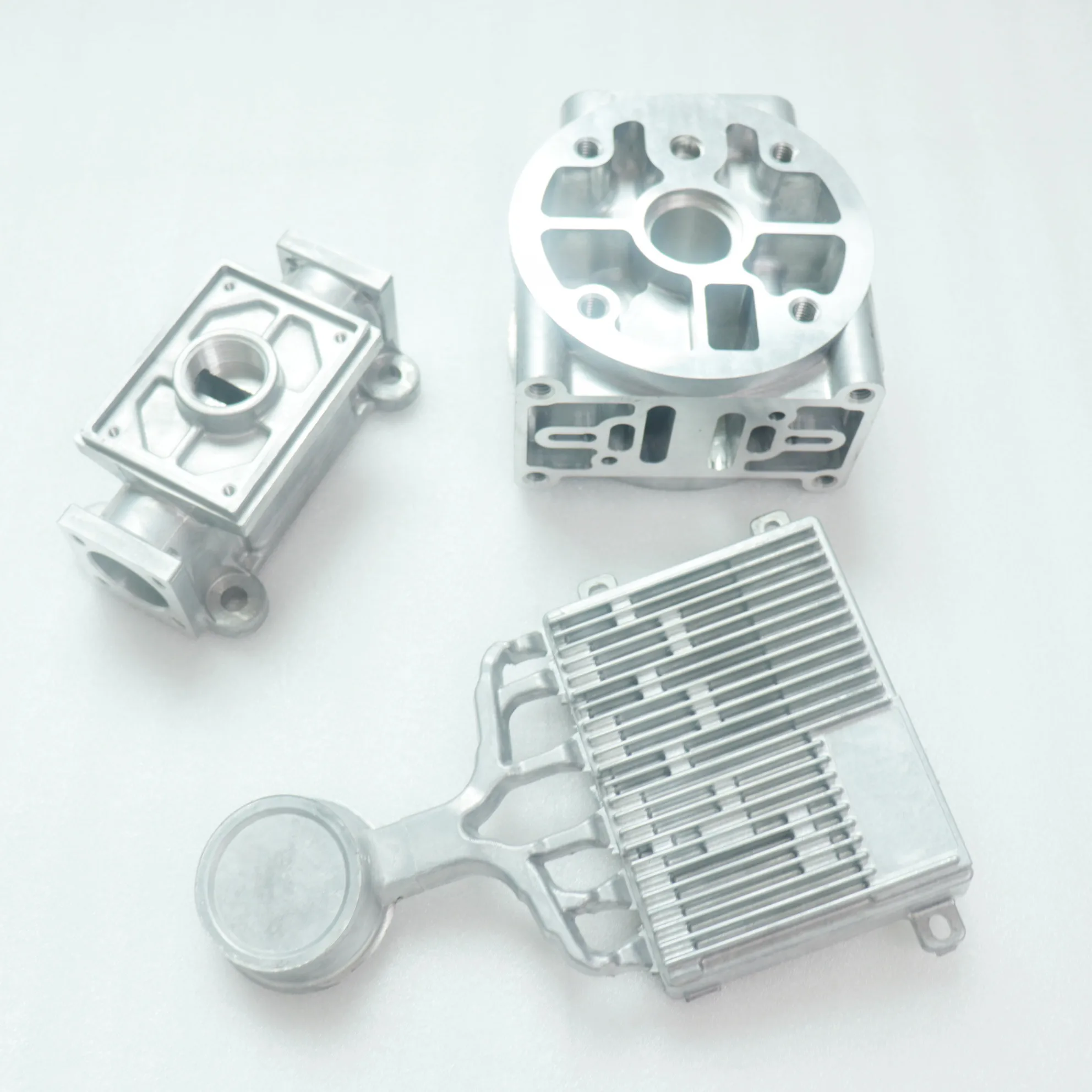

Details Images

Company Profile

Why Choose Us

You are very welcome to visit us among many suppliers

1.) We specialize in providing customized processing services for die-casting, sheet metal, CNC, and lathes.

2.) 24 hours online service & Quickly Quote.

3.) We have very rich experience, you are welcome to discuss with us at any time your requirements or products that you need to customize.

5.) 100% QC quality inspection before delivery, and can provide quality inspection form.

6.) Our products and services have been widely praised by customers at home and abroad

7.) ISO certificate Factory .

8.)In order to allow you to receive goods more quickly and conveniently, we support sea, land, express and air transportation.

We have very strict quality control process

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – All finished goods are inspected according to our quality standard for each products.

Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes out for shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will specially marked and dispose.

Customer Feedback

Certifications

FAQ

Q1:What is the specific production process? |

Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale Service. |

Q2: How soon can I get samples? |

Depending on your specific project, it usually takes 10 to 20 days. |

Q4:Can you make machining parts based on our samples? |

Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

EN

EN